Informacje o produkcie:

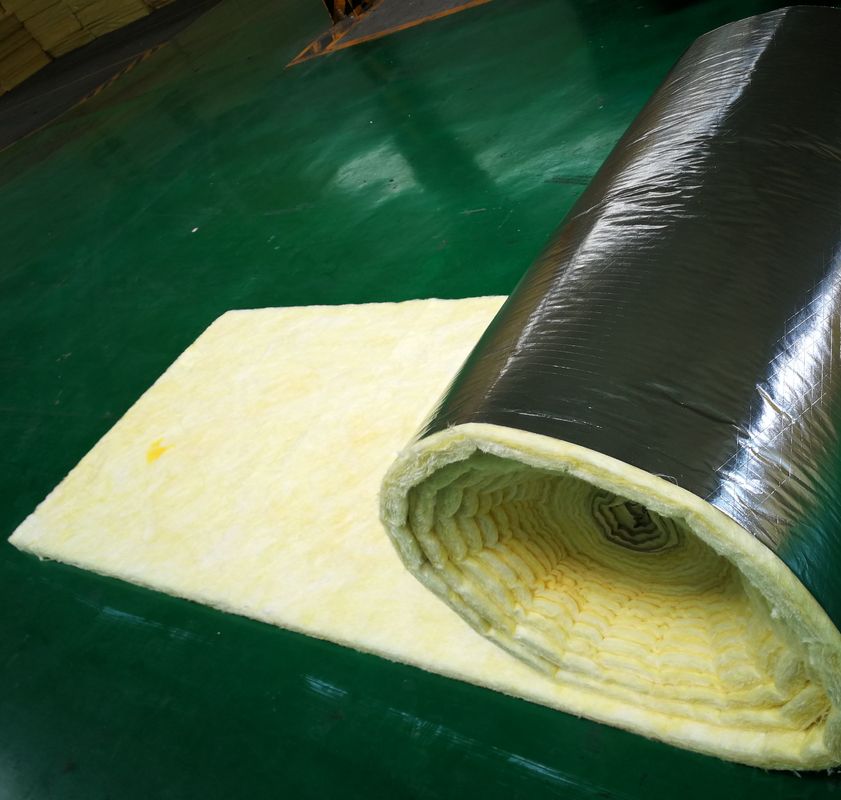

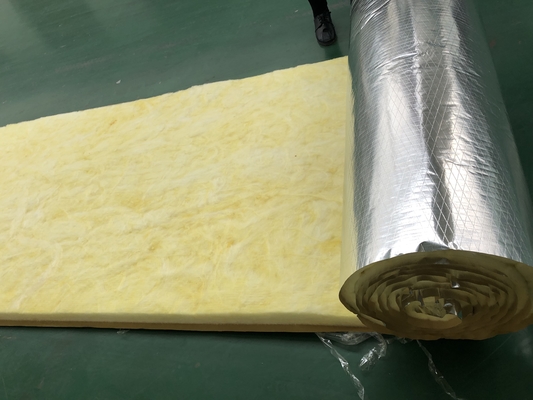

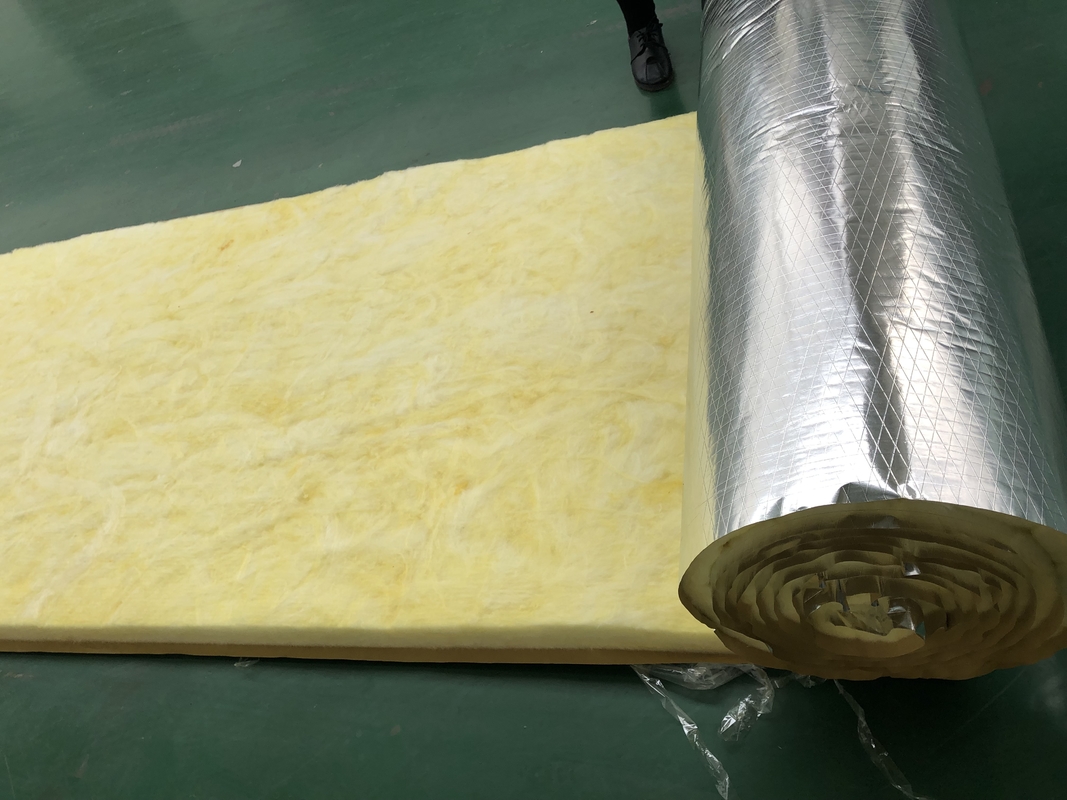

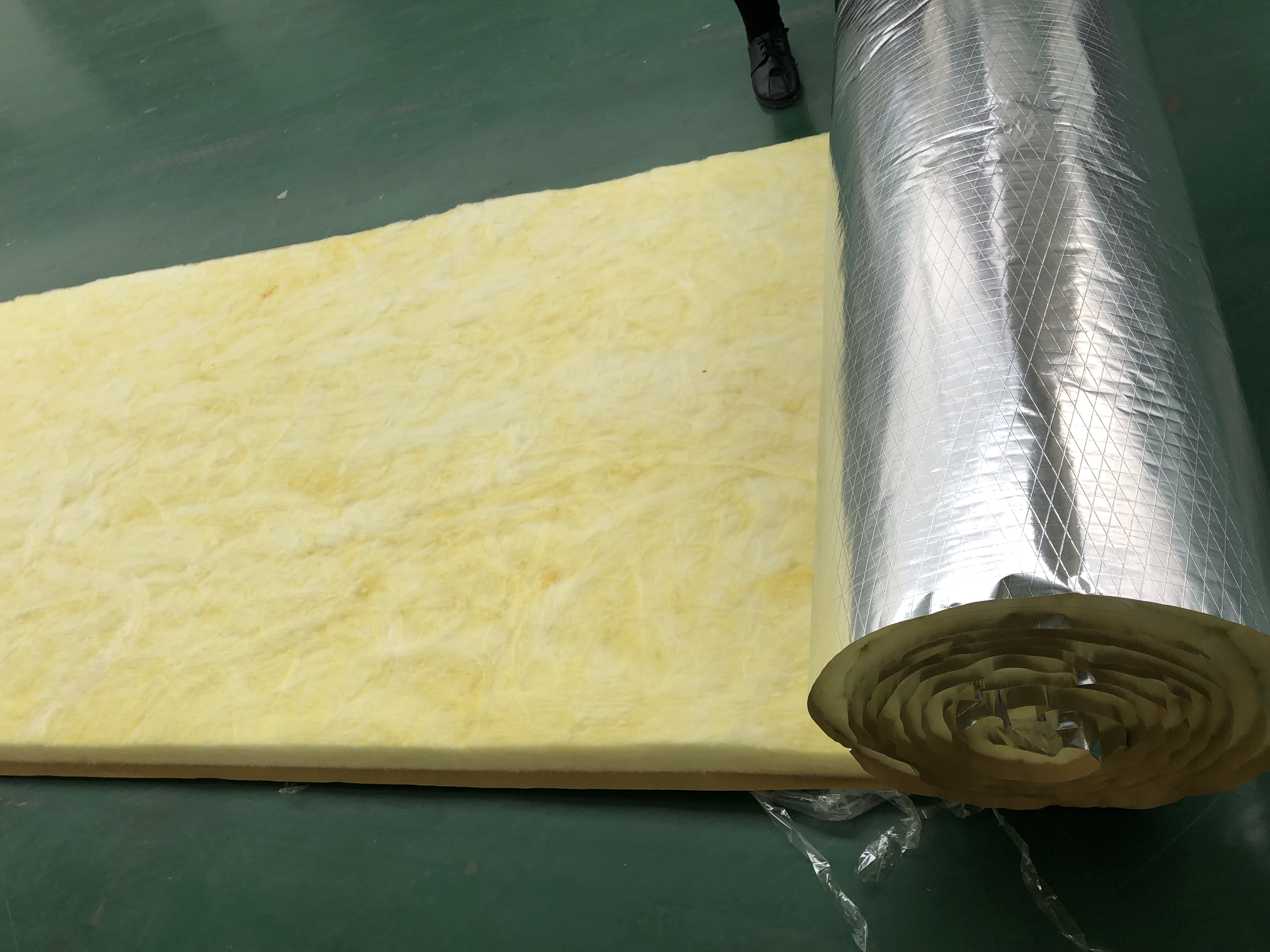

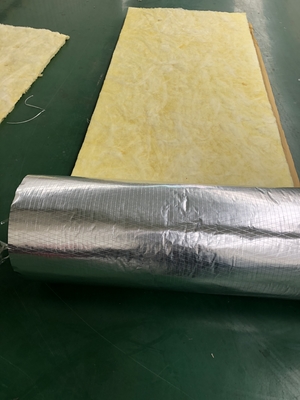

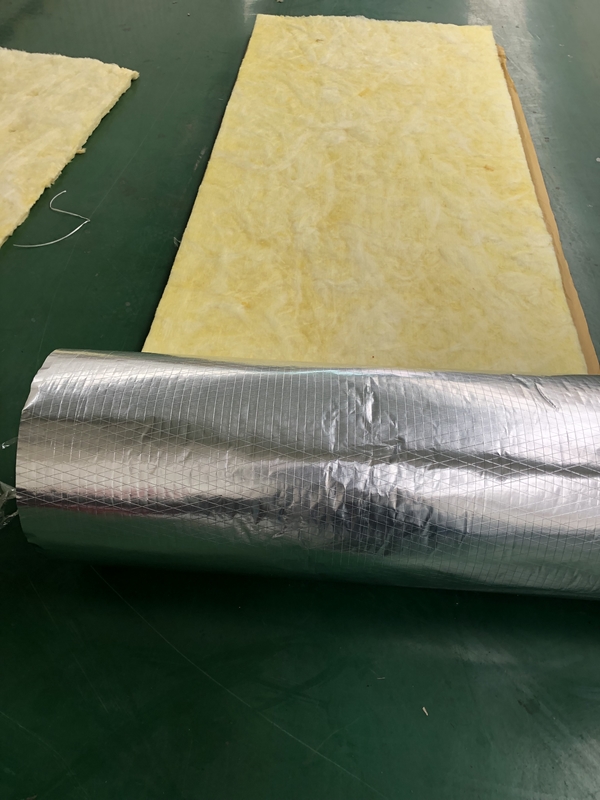

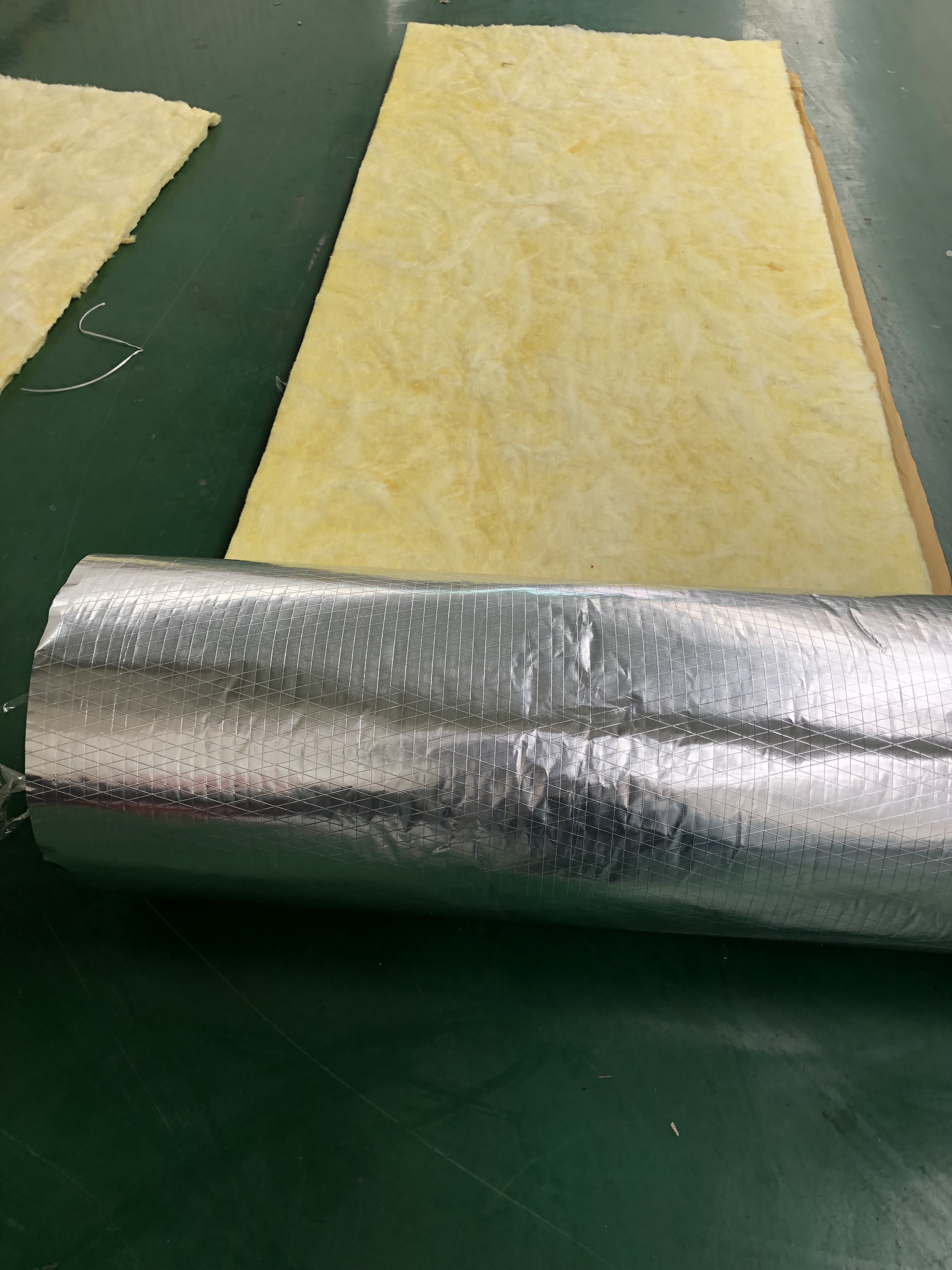

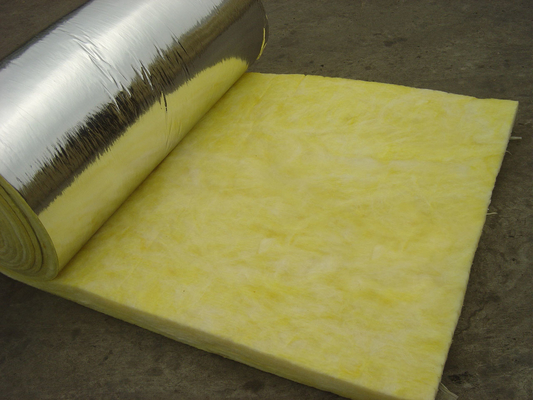

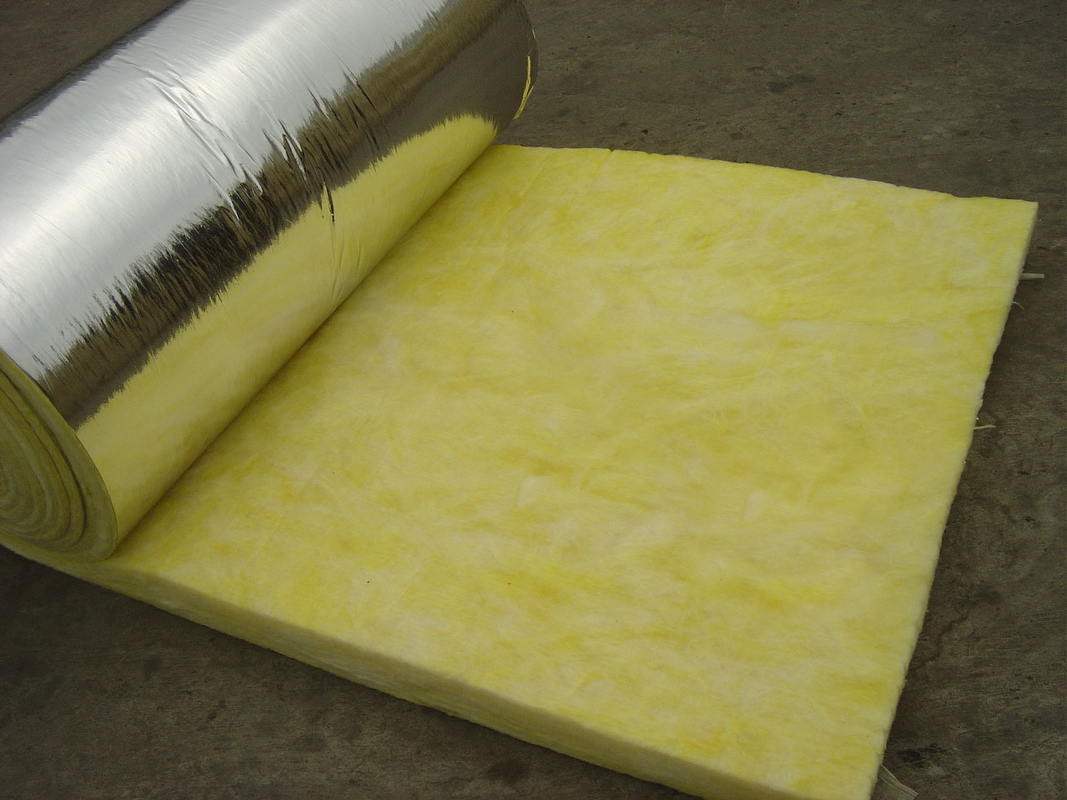

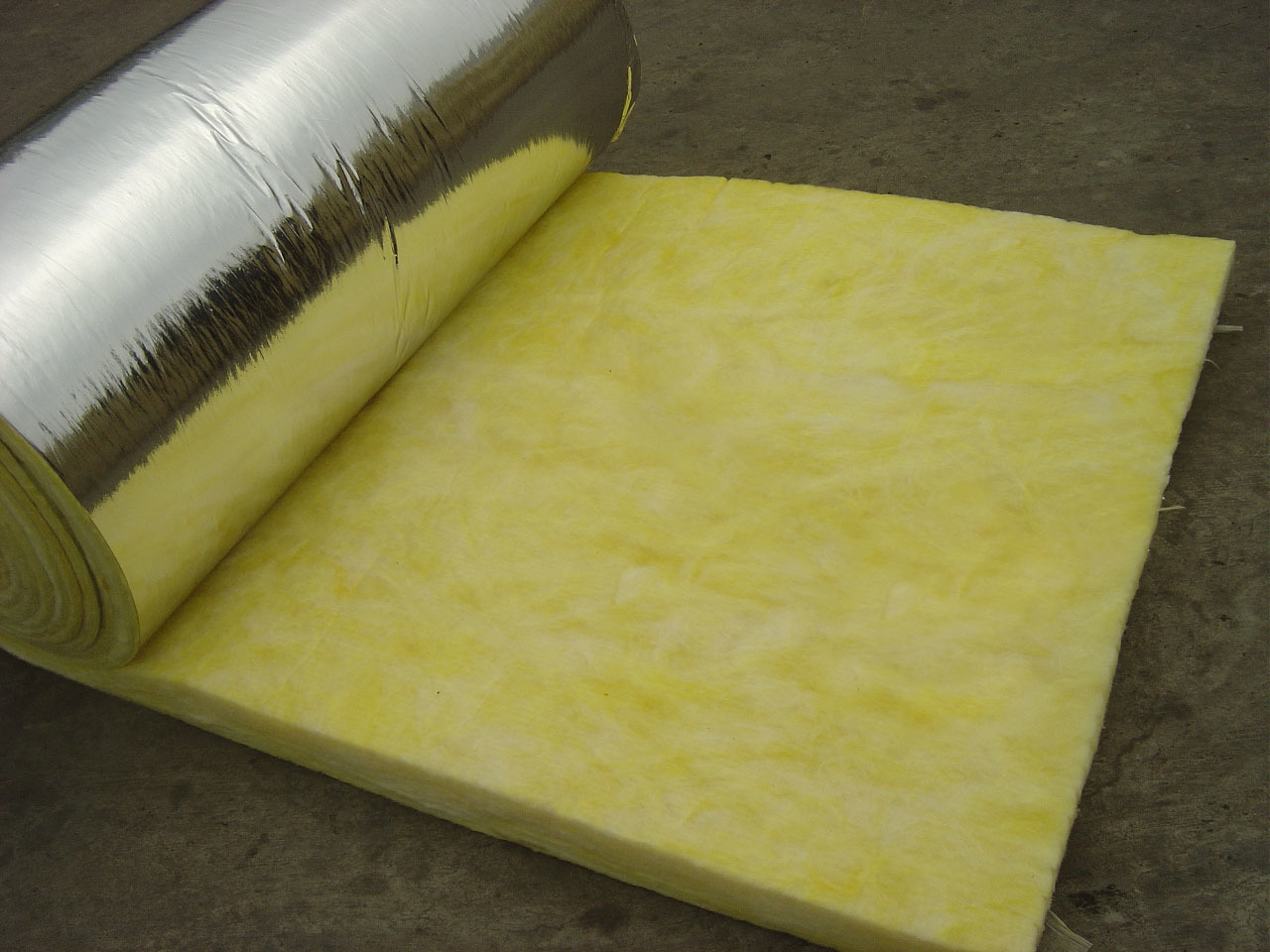

Izolacja z wełny szklanej w postaci maty odśrodkowej FANRYN jest przeznaczona do zastosowań na dużych powierzchniach. Oprócz doskonałej izolacji termicznej, skutecznie pochłania wibracje i izoluje hałas — szczególnie dźwięki o średniej i niskiej częstotliwości — zmniejszając tym samym przenoszenie dźwięku i przyczyniając się do lepszego środowiska pracy. Dostępna jest opcjonalna folia aluminiowa, która poprawia odporność na wilgoć, ochronę przed korozją i odbicie ciepła, co skutkuje zwiększoną ogólną trwałością i efektywnością energetyczną. Produkt ten jest szczególnie odpowiedni do stosowania w środowiskach, w których problemem jest higiena lub wysoka wilgotność.

Specyfikacja rolki izolacyjnej z włókna szklanego z folią aluminiową, termicznej i akustycznej, do owijania rur HVAC:

|

Gęstość (kg/m3)Grubość (m)

|

Długość (m)Szerokość (m)

|

Rolek/opakowanie10-48

|

0.025-0.25-30

|

0.6

|

|

5-8

|

2 rolki zachodzące na siebie

|

Dane techniczne rolki izolacyjnej z włókna szklanego z folią aluminiową, termicznej i akustycznej, do owijania rur HVAC:

|

5-30

|

1.1

|

|

5-8

|

2 rolki zachodzące na siebie

|

Dane techniczne rolki izolacyjnej z włókna szklanego z folią aluminiową, termicznej i akustycznej, do owijania rur HVAC:

|

0.025-0.2

|

Pozycja

|

Jednostka

|

|

5-8

|

2 rolki zachodzące na siebie

|

Dane techniczne rolki izolacyjnej z włókna szklanego z folią aluminiową, termicznej i akustycznej, do owijania rur HVAC:

|

0.025-0.2

|

Pozycja

|

Jednostka

|

|

5-8

|

2 rolki zachodzące na siebie

|

Dane techniczne rolki izolacyjnej z włókna szklanego z folią aluminiową, termicznej i akustycznej, do owijania rur HVAC:

|

0.025-0.2

|

Pozycja

|

Jednostka

|

|

5-8

|

2 rolki zachodzące na siebie

|

Dane techniczne rolki izolacyjnej z włókna szklanego z folią aluminiową, termicznej i akustycznej, do owijania rur HVAC:

|

Dane techniczne

|

Pozycja

|

Jednostka

|

Wskaźnik

|

Standard

|

|

Gęstość

|

kg/m3

|

10-48

|

GB/T 5480.3

|

|

Średnica włókna

|

μm

|

5-8

|

GB/T 5480.4

|

|

Zawartość wody

|

%

|

≤

|

1

|

|

GB/T 16400-2003

|

Główne zastosowanie rolki izolacyjnej z włókna szklanego z folią aluminiową, termicznej i akustycznej, do owijania rur HVAC:

|

1. Izolacja ścianGB 8624-1997

|

Temperatura kurczenia

|

|

℃

|

|

250-400

|

GB/T 11835-2007

|

|

Przewodność cieplna

|

w/m·k

|

0.034-0.06

|

GB/T 10294

|

|

Hydrofobowość

|

%

|

≥

|

98

|

|

GB/T 10299

|

Główne zastosowanie rolki izolacyjnej z włókna szklanego z folią aluminiową, termicznej i akustycznej, do owijania rur HVAC:

|

%≤

|

5

|

|

GB/T 5480.7

|

Główne zastosowanie rolki izolacyjnej z włókna szklanego z folią aluminiową, termicznej i akustycznej, do owijania rur HVAC:

|

1. Izolacja ścianStosowana jako warstwa izolacji termicznej dla zewnętrznych lub wewnętrznych ścian budynków, skutecznie redukując straty ciepła i poprawiając efektywność energetyczną.

|

2. Izolacja konstrukcji stalowych

|

Idealna do izolacji stalowych dachów i ścian, oferując zarówno korzyści termiczne, jak i akustyczne, a także odporność na wilgoć i korozję.

3. Wewnętrzne ściany działowe

Poprawia izolację akustyczną i termiczną ścian wewnętrznych, tworząc cichsze i bardziej komfortowe przestrzenie mieszkalne lub robocze.

4. Przedziały pociągów

Zapewnia lekką izolację termiczną i akustyczną dla pojazdów kolejowych, poprawiając komfort pasażerów i przyczyniając się do oszczędności energii.

5. Absorpcja dźwięku i izolacja akustyczna

Szeroko stosowana w studiach, kinach i pomieszczeniach technicznych w celu zmniejszenia przenoszenia hałasu i poprawy środowiska akustycznego.

6. Izolacja kanałów HVAC

Owijana wokół kanałów wentylacyjnych, aby zapobiec stratom lub zyskom ciepła, kontrolować kondensację i zmniejszyć hałas operacyjny.

Normy:

Zgodnie z NORMAMI GB, EN13162, EN13172, ISO9001:2000

Zalety:

1. Doskonała sprężystość: Powraca do pierwotnej grubości w ciągu 24 godzin po rozpakowaniu, zapewniając stałą wydajność i łatwą instalację.

2. Jednolita grubość i kolor: Oferuje wysoką spójność wyglądu i wymiarów, zapewniając schludne, profesjonalne wykończenie.3. Doskonała stabilność wymiarowa: Utrzymuje integralność strukturalną w czasie, nawet w zmiennych warunkach środowiskowych.

4. Zmniejszone podrażnienie włókien: Zawiera miękkie, długie włókna szklane i zaawansowaną technologię wiązania, aby zminimalizować wypadanie włókien, poprawiając bezpieczeństwo i komfort instalacji.

Szczegóły:

Pakowanie

:

1. Worek z tworzywa sztucznego próżniowego + tkany worek

2. Worek z tworzywa sztucznego próżniowego + tkany worek + worek PE

3. Worek z tworzywa sztucznego próżniowego + worek termokurczliwy PEO2: Nasz standardowy pakiet to worek z tworzywa sztucznego próżniowego + tkany worek (Standardowe opakowanie eksportowe).

FAQ

:

P1: Jak zagwarantować jakość produktów?

O1: Nasz doświadczony zespół kontroli jakości sprawdzi jakość produktu w każdym procesie

P2: Jak pakować eksportowane towary?O2: Nasz standardowy pakiet to worek z tworzywa sztucznego próżniowego + tkany worek (Standardowe opakowanie eksportowe).

P3: Jaki jest czas realizacji zamówienia na jeden kontener 40HC?

O3: Zazwyczaj 7-10 dni roboczych po złożeniu zamówienia.

P4: Jaka jest Twoja przewaga w przypadku maty z wełny szklanej?

O4: Naszą matę z wełny szklanej można dowolnie ciąć podczas budowy zgodnie z wymaganym kształtem.

P5: O obsłudze posprzedażnej, jak rozwiązać problemy, które wystąpiły u Twojego klienta zagranicznego na czas?

O5: Gwarancja na nasze produkty wynosi jeden rok. Jeśli nasze produkty lub opakowanie mają problem z jakością, wymienimy je lub zrekompensujemy odpowiednio.

Nasza usługa

- Roczna gwarancja na wszystkie produkty

- Niezbędne wsparcie techniczne

- Dostarczanie wysokiej jakości produktów z doskonałą obsługą na czas

- Dostarczanie kompleksowego rozwiązania w zakresie produktów izolacyjnych i wentylacyjnych

- Dostarczanie wysokiego poziomu obsługi kontroli jakości

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!